WhatsApp/WeChat:

+86 18994470782

+86 18994319892

E-mail:

laserhy@126.com

Jeanyjin@laserhy.com

Address:

Building 14, No.399 Gongtang Road, Luzhi Town, Wuzhong District, Suzhou, Jiangsu, CHINA (215127)

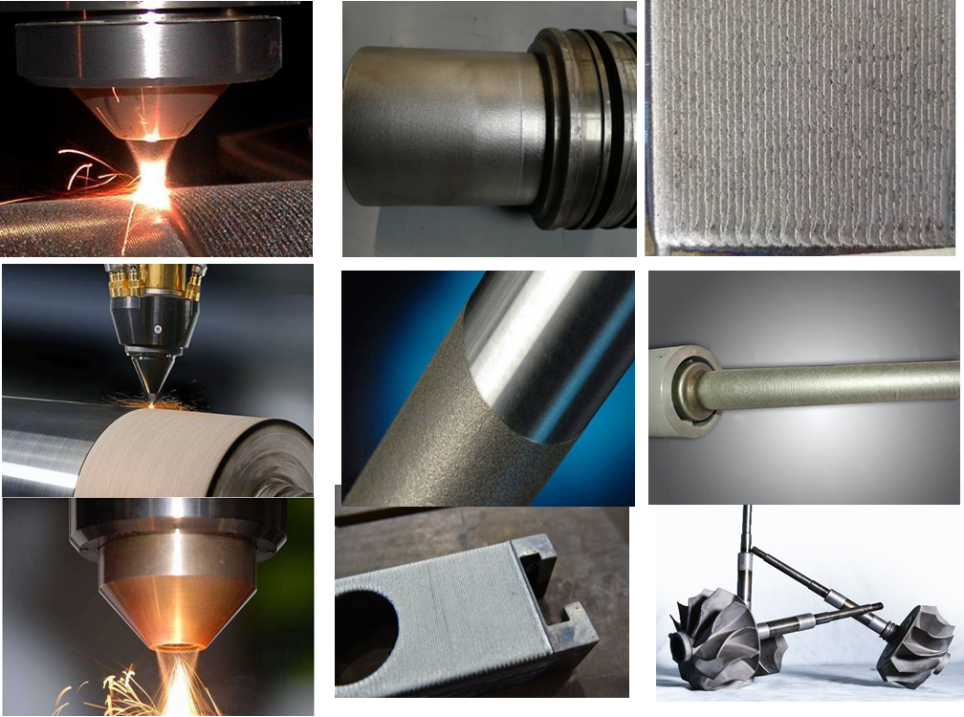

Laser cladding machine is a laser processing technology that uses high-energy density laser beam to quickly heat and melt the cladding material and substrate surface, forming a molten pool on the substrate surface, and forming a certain thickness of metallurgical bonding layer on the substrate surface after cooling and solidification.

Features and advantages:

Compared with common surfacing and plasma spray welding (coating), laser cladding technology has a series of outstanding characteristics:

- The micro-structure of the cladding layer is fine and dense, and the hardness of the coating is higher, with better corrosion resistance and wear resistance.

- The coating and the matrix are metallurgic ally bonded.

- Small heat affected zone and less work piece deformation. Low dilution rate of cladding layer (only 5%~8%), a thinner coating can make the required performance.

- High power density of laser beam, high heating temperature, and wider selection range of cladding materials.

<!--[if !supportLists]-->- <!--[endif]-->The coating quality is stable and easy to realize automatic production.

<!--[if !supportLists]-->- <!--[endif]-->The surface roughness after cladding can reach Ra25 μ m; It is suitable for a variety of anti-corrosion, wear-resistant and anti-oxidation functional coatings.

Model | HY-RF01 |

Wavelength | 1.06µm |

Max Laser Power | 1-20KW |

Motion Mode | Robot or 4 or 6-axis platform |

Cabinet | Open or Close Optional |

Laser Processing Head | 0.8-50mm round and square light spot, and the size can be customized, Coaxial and side shaft powder feeding nozzles |

Powder Feeder | Pneumatic and gravity conveying, powder feeding accuracy ≤± 2%, powder feeding volume 10-150g/min |

Position System | Red Light +CCD |

Power Supply | 380V/50&60Hz/40A |

Cooling Method | Water Chiller integrated |

Application:

Applicable to metallurgy, mold, machinery manufacturing, petrochemical, light industry, military industry and other industries.